Reference Profile

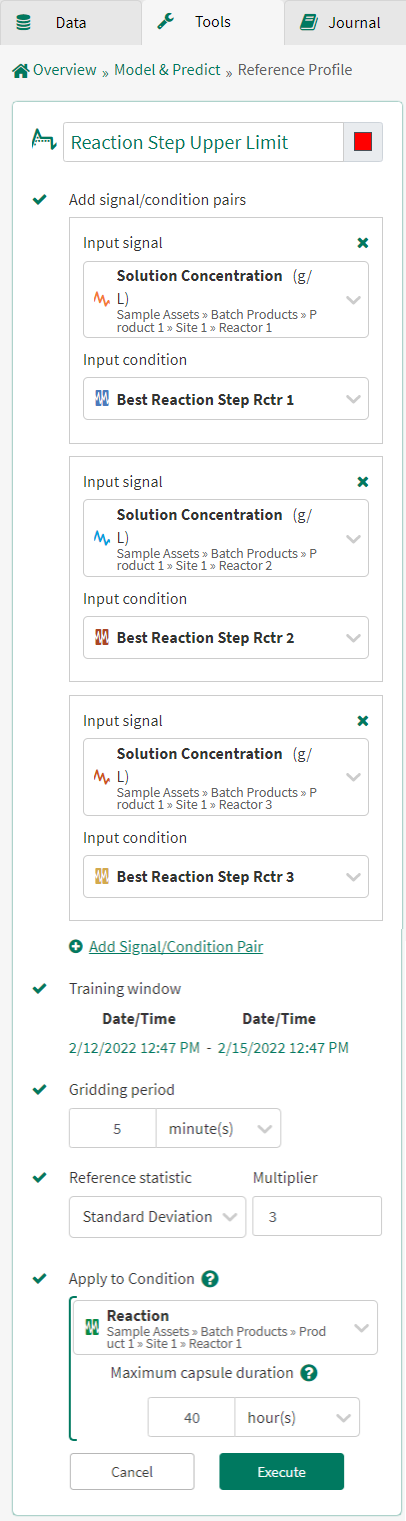

The Reference Profile tool enables users to characterize a signal's behavior. This tool creates a profile by aggregating signal trends within a condition over a user-defined training window. This tool is commonly used to create control limits for Statistical Process Control (SPC) and to create signal boundaries.

Using the Reference Profile Tool

Reference Statistic

The Reference Statistic input identifies the statistic that is used to calculate the Reference Profile. The Average, Minimum and Maximum Reference Profiles do not require a multiplier. All other reference profiles are calculated as follows:

RefProf = AvgRefProf + Multiplier*(RefStatistic)

RefProf = calculated Reference Profile using the selected Reference Statistic

AvgRefProf = the Average Reference Profile (discussed below)

Multiplier = the Reference Statistic multiplier specified by the user in the Reference Profile tool

RefStatistic = the Reference Statistic specified by the user int eh Reference Profile tool

The Multiplier may be positive or negative. If '0' is used for the Multiplier, the Average Reference Profile is calculated.

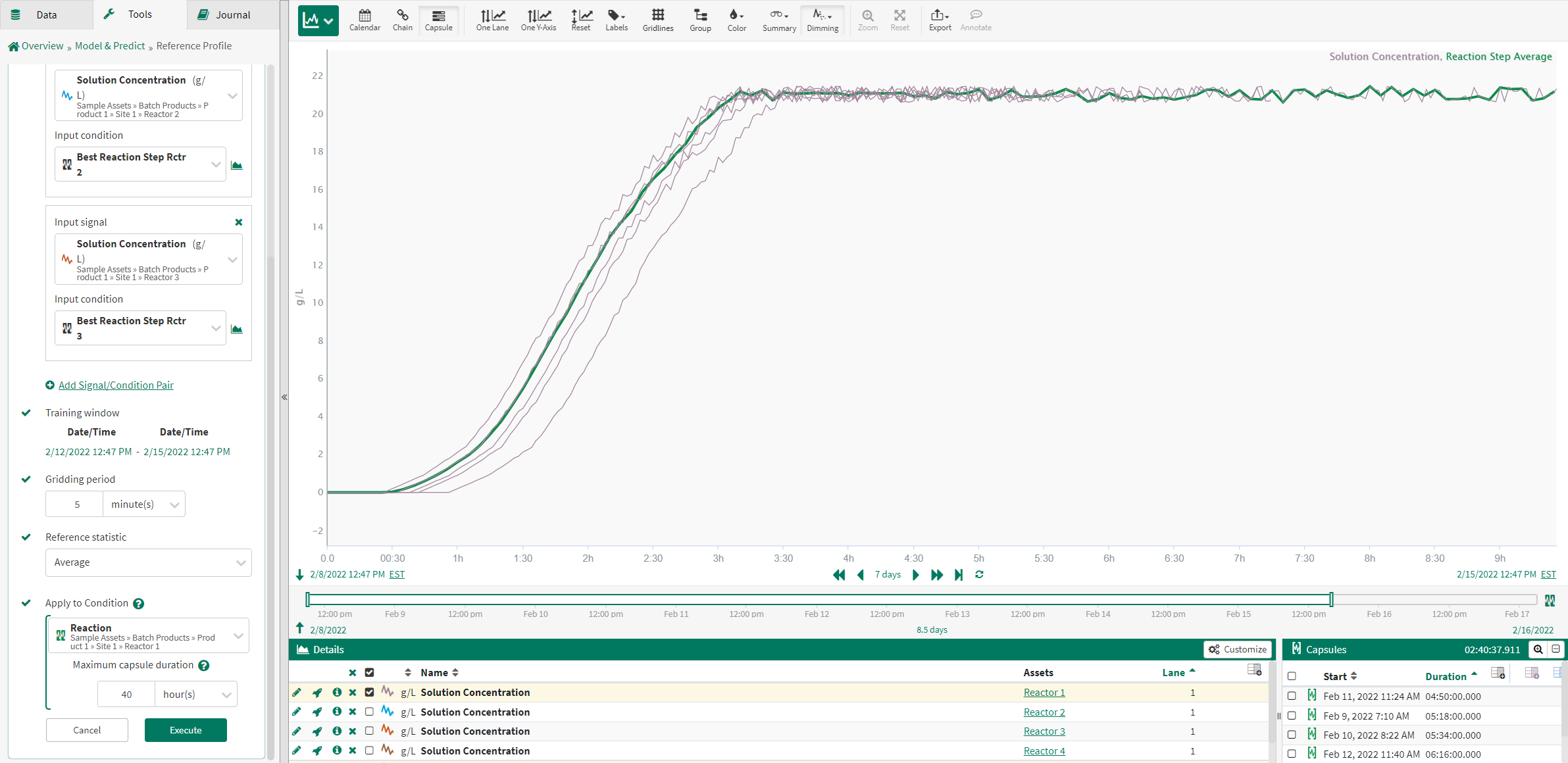

Average

Selecting Average for the Reference Statistic calculates the Reference Profile as the average of the input signal during each capsule of the Input Condition(s) over the training window. All other Reference Statistics are based upon this Average Reference Profile.

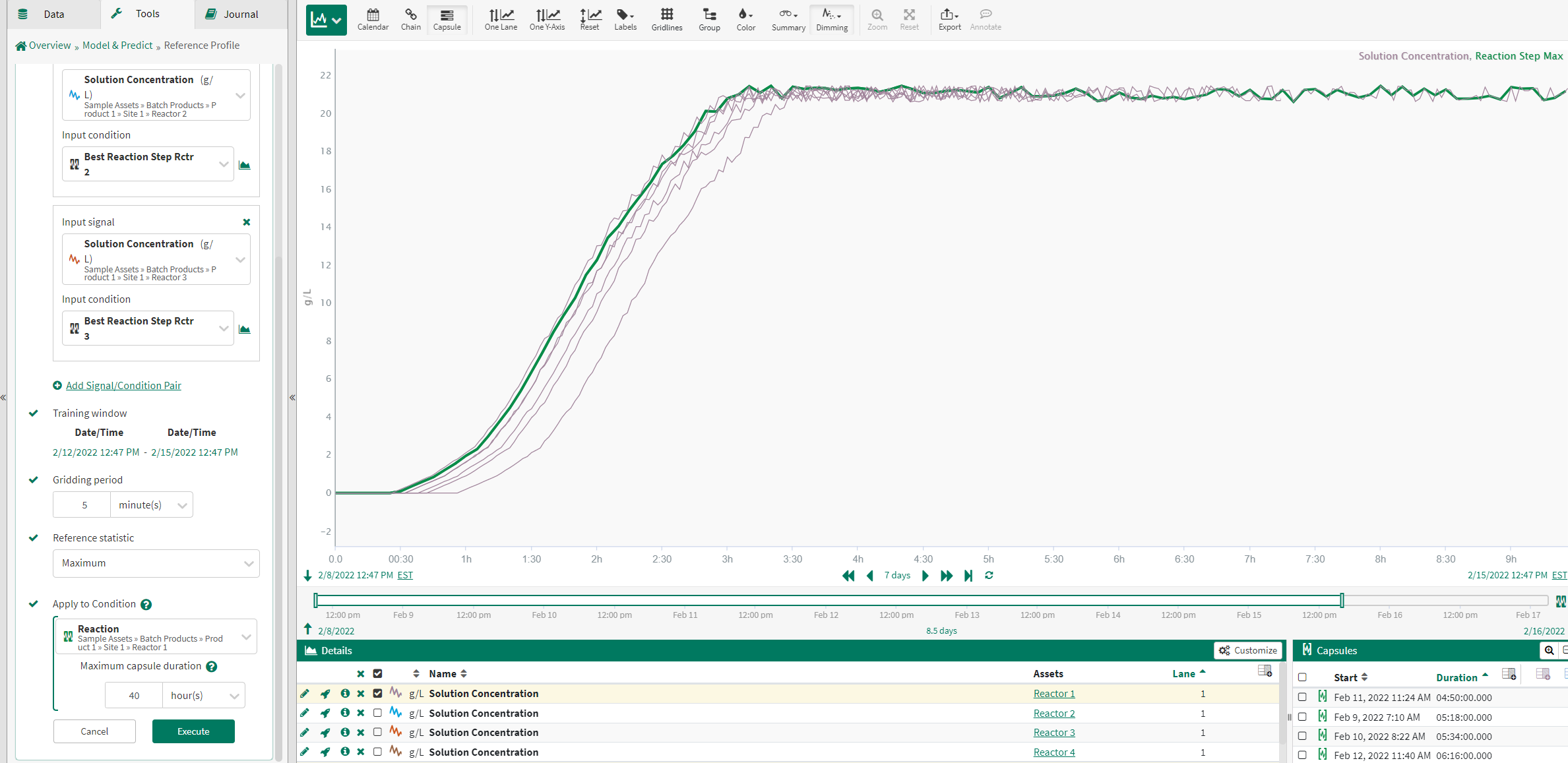

The example to the right shows an Average Reference Profile created based upon a signal's performance during several “Best” capsules used in the signal/condition inputs.

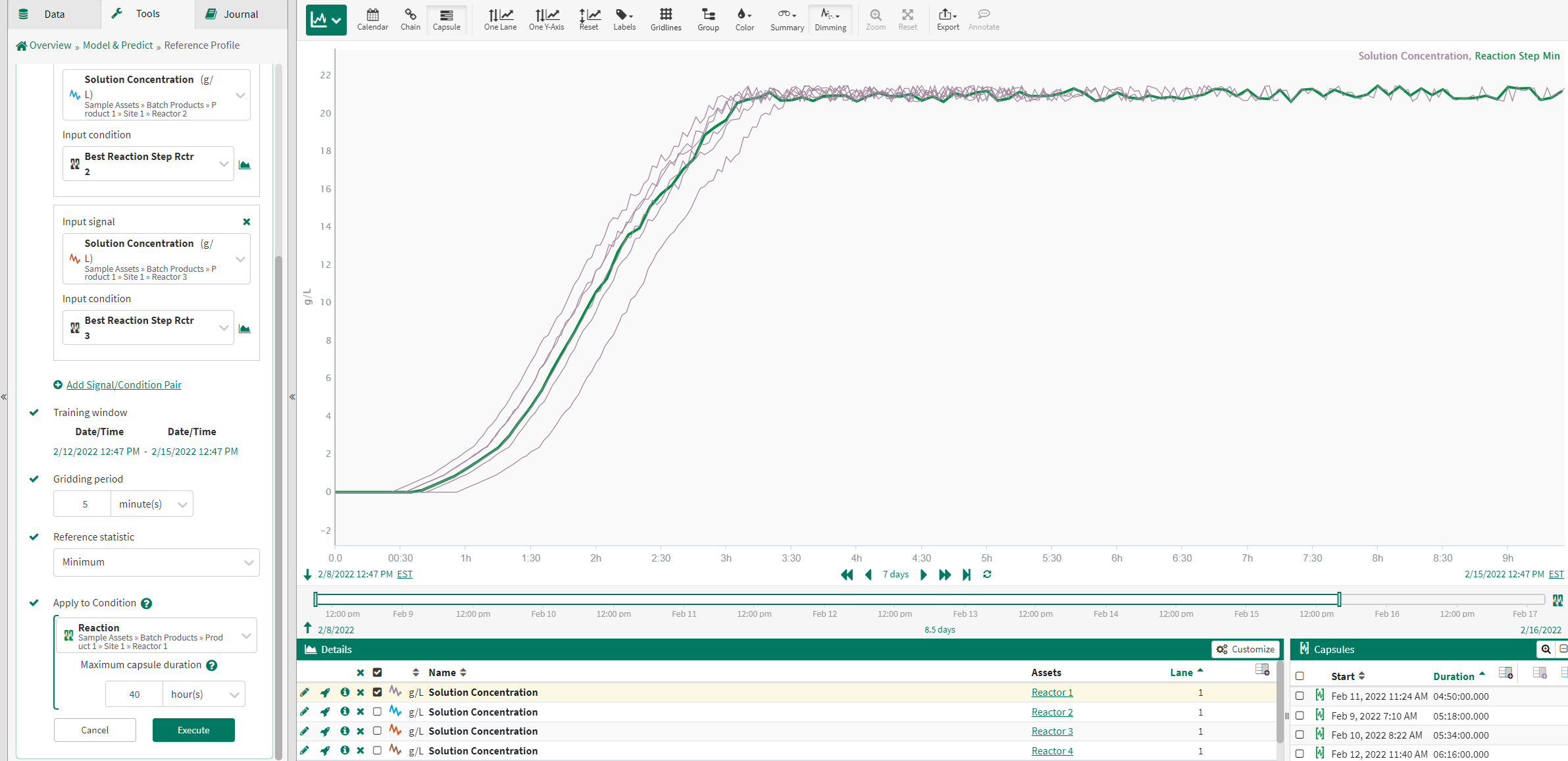

Minimum

Selecting Minimum for the Reference Statistic calculates the Reference Profile as the minimum of the input signal during each capsule of the Input Condition over the training window.

The example to the right shows an Minimum Reference Profile created based upon a signal's performance during several “Best” capsules used in the signal/condition inputs.

Maximum

Selecting Maximum for the Reference Statistic calculates the Reference Profile as the maximum of the input signal during each capsule of the Input Condition over the training window.

The example to the right shows an Maximum Reference Profile created based upon a signal's performance during several “Best” capsules used in the signal/condition inputs.

Average, Maximum and Standard Deviation

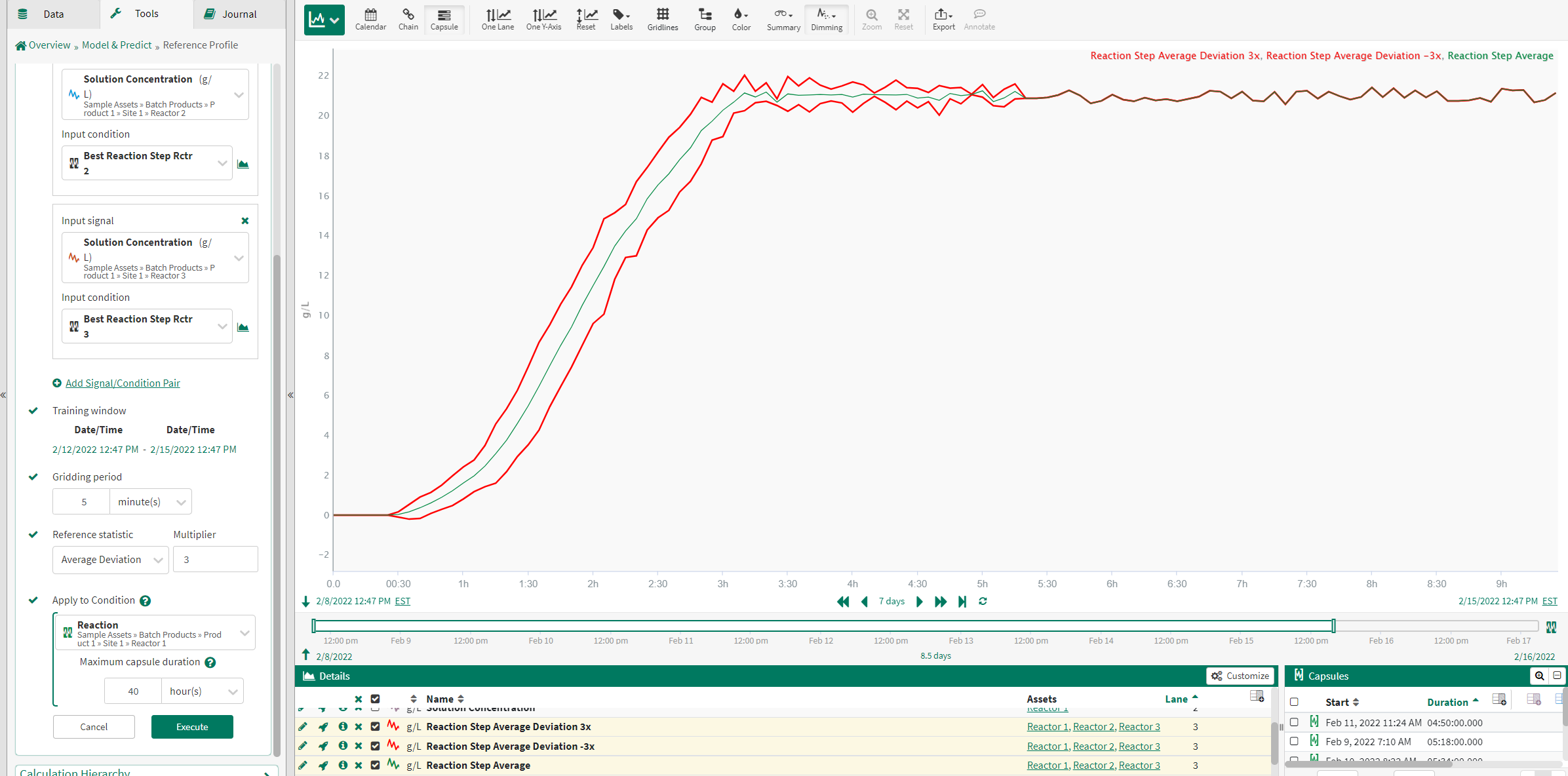

Selecting Average, Maximum or Standard Deviation for the Reference Statistic calculates the Reference Profile as:

RefProf = AvgRefProf + Multiplier*Dev

RefProf = calculated Reference Profile using the Average Deviation Reference Statistic

AvgRefProf = the Average Reference Profile (discussed above)

Multiplier = the Reference Statistic multiplier specified in the Reference Profile tool

Dev = the Average, Maximum or Standard Deviation of the input signal.

The example to the right displays two Average Deviation Reference Profiles, one with a +3 multiplier and one with a -3 multiplier, compared to the Average Reference Profile.

Example

In this example use case, a process has an expected behavior during a phase transition. The Reference Profile tool is used to characterize this expected behavior and set upper and lower limits for the input signal during these phase transitions. With the limits set, excursions outside of these limits are easily identified.

1. Identify Profile of Interest

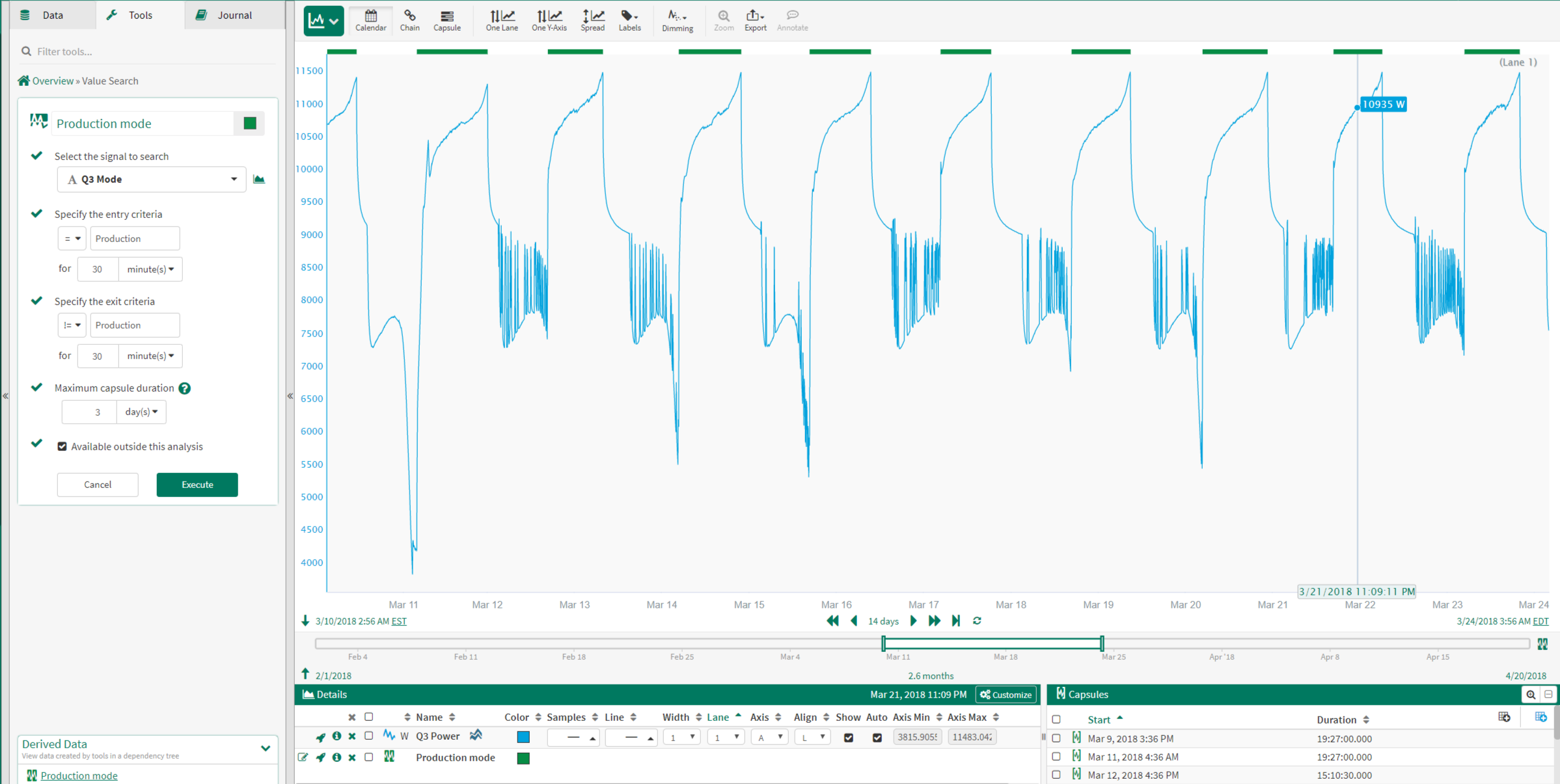

The phase transitions are easily identified using Value Search on the mode tag.

The image to the right shows the Value Search used to identify the 'Production mode' condition.

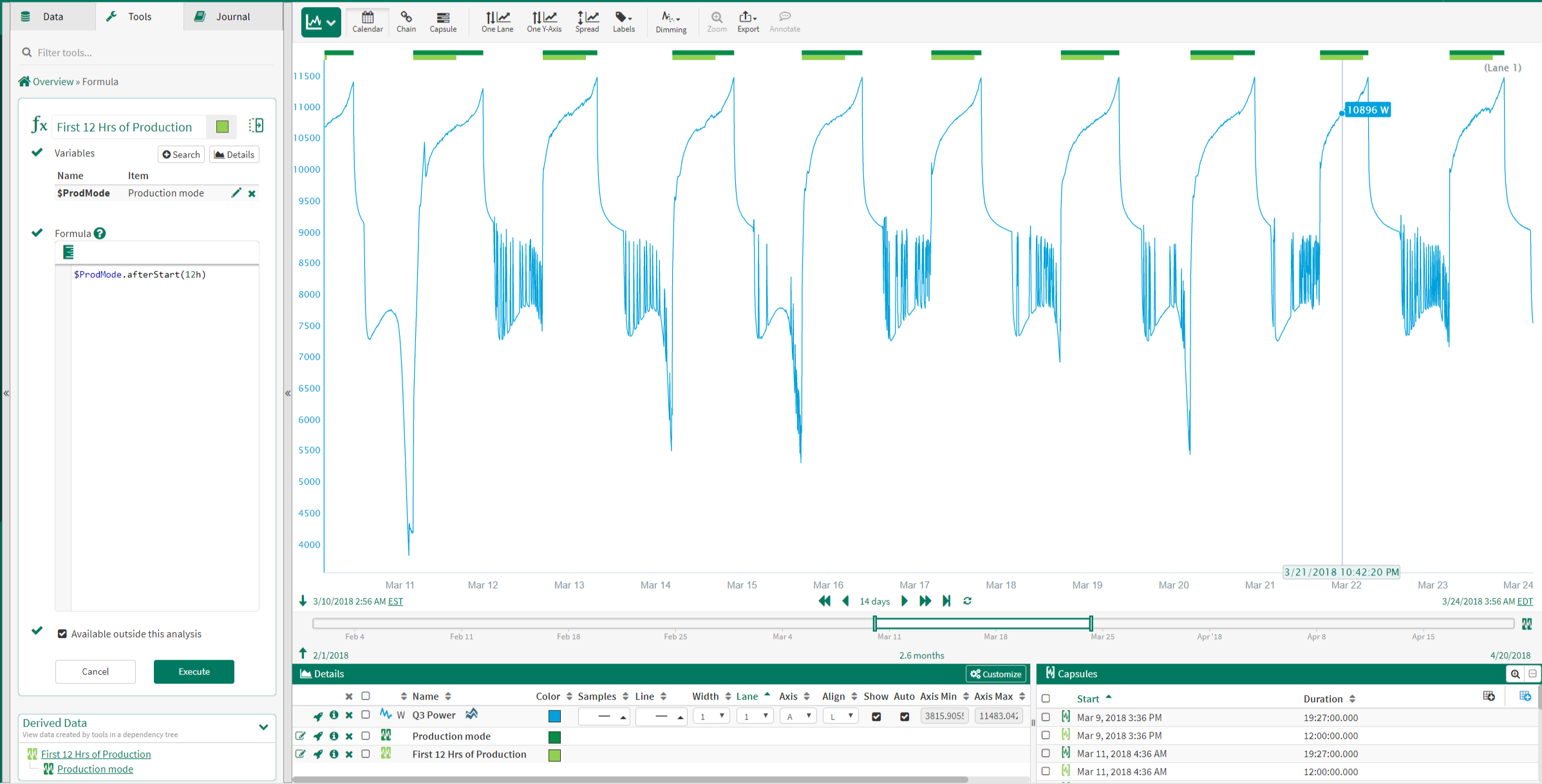

Since the durations of the 'Production mode' capsules vary, Formula is used to identify just the first 12 hours of production. This ensures that the Reference Profile is created using capsules of equal duration.

The image to the right shows the Formula used to identify the 'First 12 Hrs of Production' condition.

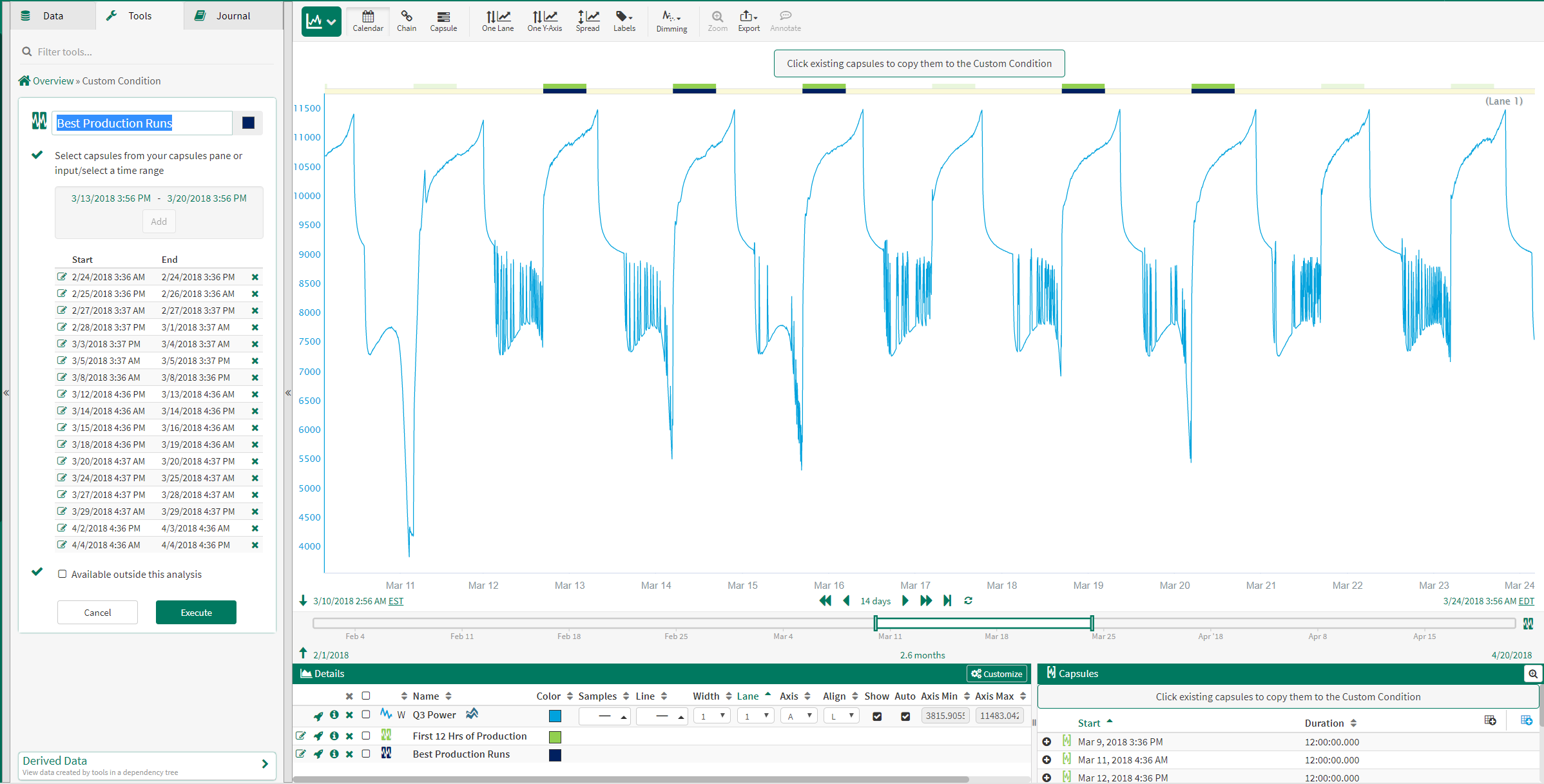

2. Identify Best Production Runs

The best production runs are manually selected using the Manual Condition tool. The capsules in the this 'Best Production Runs' condition will be used to create the Reference Profile.

The image to the right shows the Manual Condition used to create the 'Best Production Runs' condition.

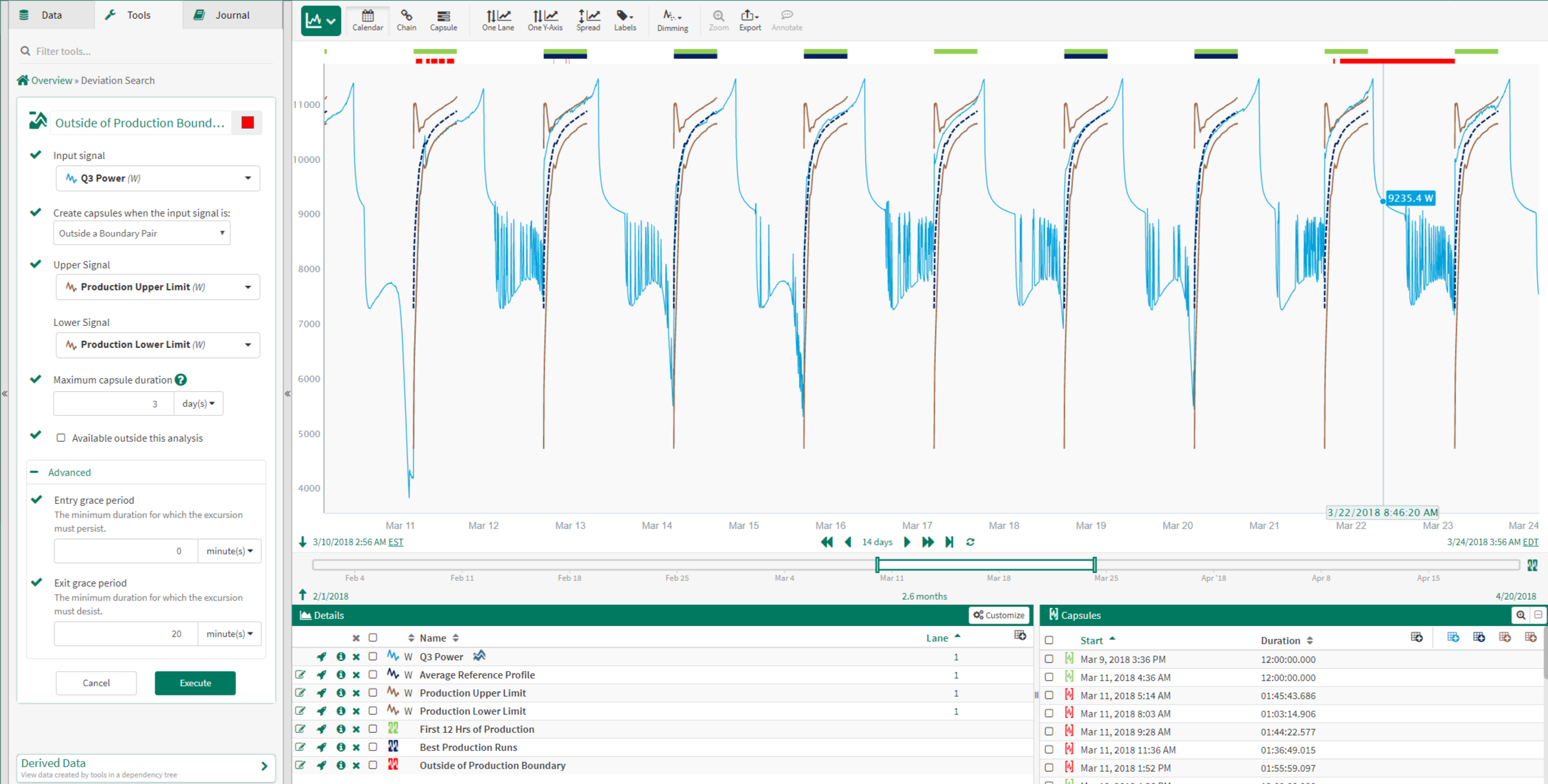

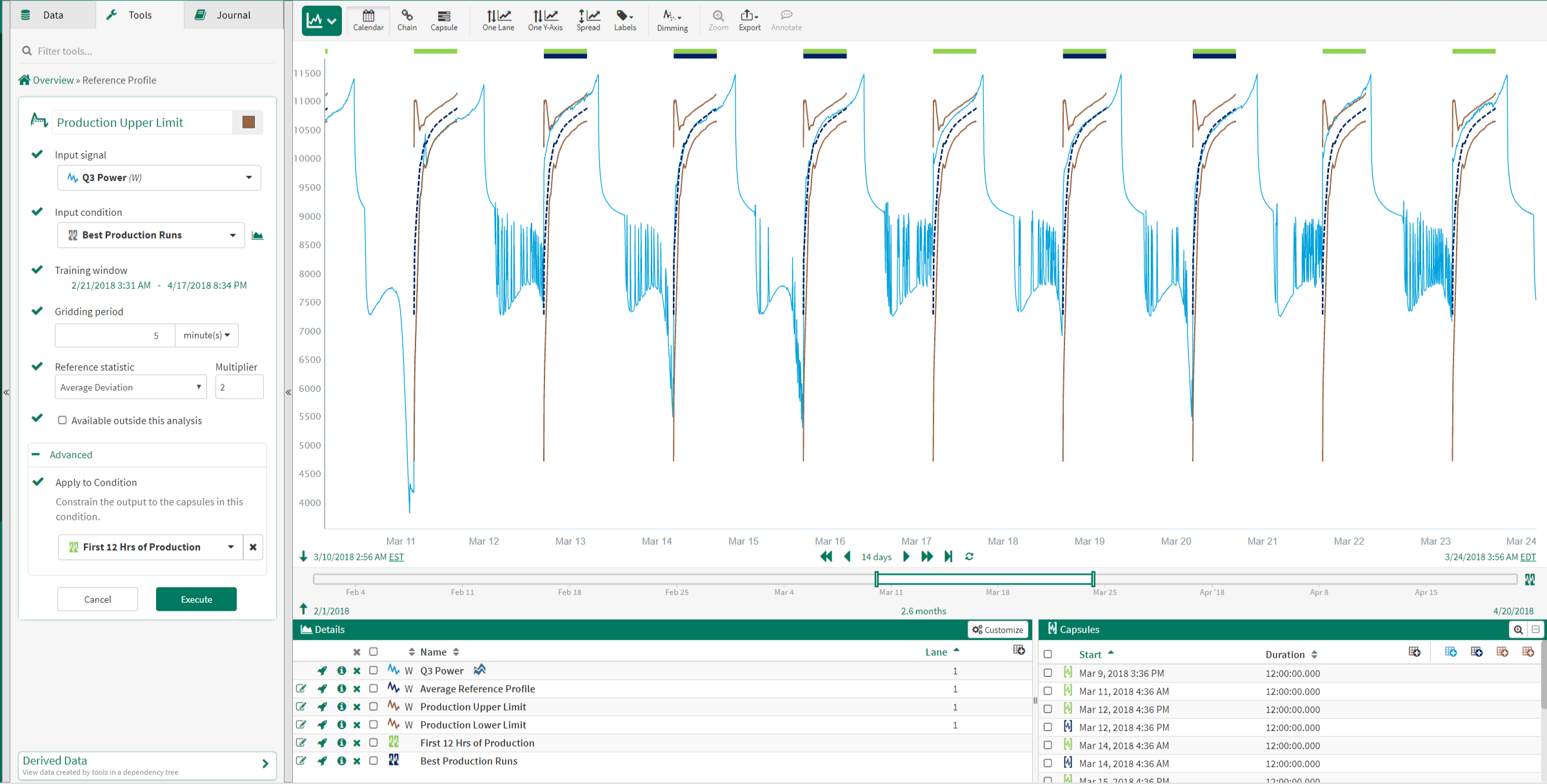

3. Calculate Reference Profile(s)

The Reference Profile tool is used to create 3 reference profiles: an Average Reference Profile, a +2 Average Deviation Reference Profile and a -2 Average Deviation Reference Profile.

The image to the right shows the inputs used to calculate the Production Upper Limit profile. The calculated profiles are applied to the input signal during the 'First 12 Hrs of Production' condition.

Note: steps 1 and 2 can be repeated for multiple assets in order to include Best Production Runs from multiple assets to be used as signal/condition pairs.

4. Identify Excursions

The Value Search tool is used to identify when the input signal deviates outside of the upper or lower limit.

The image to the right identifies time periods when the input signal exceeds the upper and lower reference profiles.